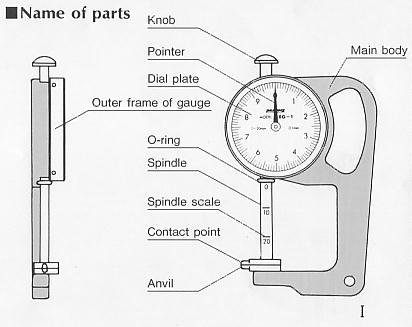

How to use Snap Caliper ( EG-1, EG-2 ) How to use Snap Caliper ( EG-1, EG-2 ) |

|

To measure thickness and diameter of balls : To measure thickness and diameter of balls : |

| (1) |

First, press down a knob to check whether a pointer shows 0. |

| (2) |

As shown in the drawing II , put an object for measurement between a contact point |

|

and anvil, and read a position of pointer on a dial plate. A division of scale is 0.1 mm, |

|

so read the values on the dial 1, 2, 3... as 1, 2, 3 mm... ( After one rotation, it shows 11, |

|

12, 13 mm... ) |

| (3) |

One rotation of a pointer shows 10 mm. Check whether it is first or second rotation by |

|

reading a spindle scale indication. |

|

( Example ):A pointer shows 6 at your measurement: |

|

1st rotation --> 6 mm, 2nd rotation --> 16mm |

|

|

To measure groove width and inner diameter : To measure groove width and inner diameter : |

| (1) |

Press down a knob and have a contact point and anvil contacted fast, then rotate an |

|

outer frame of gauge so that a division of 3 on a dial plate meets a position of pointer. |

| (2) |

Pressing down a knob by your fingers, insert the tips of contact point and anvil into the |

|

inside of an object for measurement, and slowly release a knob, as shown in the |

|

drawing III |

|

( Notice ) :Measure an object at right angles to a groove. If you measure it diagonally, |

|

a value larger than the actual one will be indicated. |

|

|

To measure depth and step depth -( EG-2 only is available. ) To measure depth and step depth -( EG-2 only is available. ) |

| (1) |

Rotate an outer frame of gauge so that a pointer meets 0 on a dial plate, by putting |

|

a flat plate on the reference level of gauge. ( If there is no adequate plate, put your |

|

gauge upside down, and press the reference level of gauge on a flat table ). |

| (2) |

Press your gauge down to the measuring part of an object for measurement, as |

|

shown in the drawing IV |

|

|

Major Specifications Major Specifications |

| (1) |

A division of scale |

0.1mm |

| (2) |

Measuring Range |

for measurement of thickness |

0 ~ 20mm |

|

|

for measurement of inner diameter |

3 ~ 23mm |

|

|

for measurement of depth |

0 ~ 20mm |

| (3) |

Weight |

EG-1 ; 97g |

EG-2 ; 100g |

|

Remarks Remarks |

|

After your finising measurements of internal diameter and step depth, adjust a pointer so |

|

as to meet 0 on a dial plate for thickness measurement. |

|