Máy đo kích thước bằng quang học MTP 170 VICIVISION INSPECTION MICROCHECK

FAST: scanning the entire area is done in just 10 seconds, significantly reducing inspection time

FLEXIBLE: you examine several pieces simultaneously, making it ideal for control of parts at the end of the production line.

PRACTICE: a large working area of 170 x 300 plan with precision unique in its category.

SIMPLE: pieces can make freehand or automatically to a loading / unloading easy and fast.

PRECISION: has the ability to capture images for control over the small pieces.

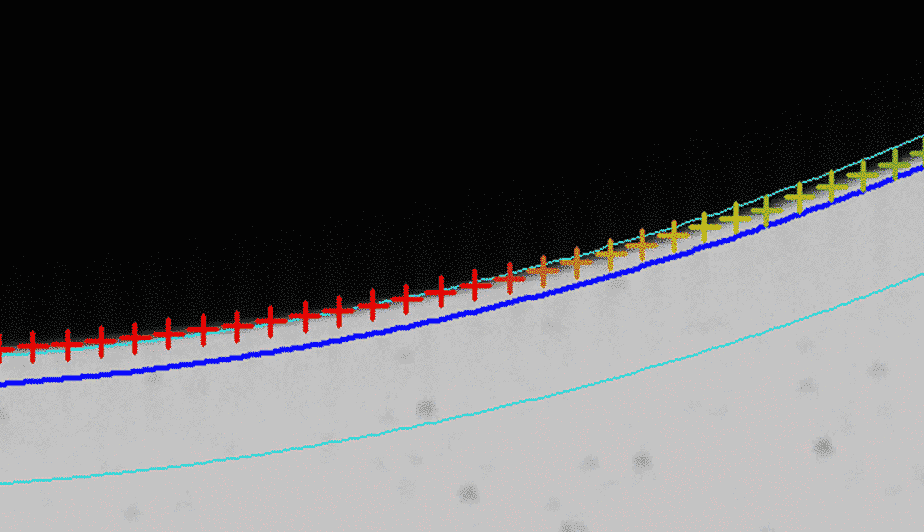

DXF: compare theoretical profile or part thereof, with thousands of points taken part.

It can measure parts up to 170 x 300 x 10 mm

Results are displayed in histograms, graphs and reports.

Choose the best equipment to analyze the produced parts.

• Connectors fluid fittings • • • Parts type ax

• Parts multi-axis • Precision Screws Pini • • • Rivets • Screws rolled

• Screws and bolts • Casting •

• Casting electrical components •

• pinion shafts • Valves • Valves • Pistons hydraulic •

• Valves • Pneumatic Cylinders • • Turned Parts

• Dental Implants • shafts • Gears • Screws •

• Medical • Turbines • Screw compressors Turbo camshafts • •

• Clock • Parts

• Burners • Crankshaft • • Auto Axles